Standard Operating Procedure (SOP) and Work Instruction (WI) Writing Services

APS creates highly effective procedures for operations, maintenance, quality, safety, and administration.

APS provides Standard Operating Procedure (SOP) writing services for all types of industrial equipment and manufacturing and service processes.

Our visual SOPs provide an effective tool to train your workforce and ensure optimal job performance. They ensure regulatory compliance, optimize quality, and standardize processes across multiple shifts or locations.

Since our founding in 1994, APS has written more than 100,000 standard operating procedures (SOPs) and work instruction for our customers worldwide.

Stop writing SOPs that nobody uses!

Does your SOP system consist of a dusty binder that sits on a shelf that nobody uses? Do your people complain that your SOPs are not relevant or useful? We can help!

Our experts create effective procedures that are clear, concise, and accurate. Over the years, we have learned (sometimes the hard way) what works and what doesn’t work. Our highly visual format results in procedures that are easy to use and that people want to use.

Our customers tell us that our procedures are the best in the industry. These are the procedures that people actually use… the procedures that get results.

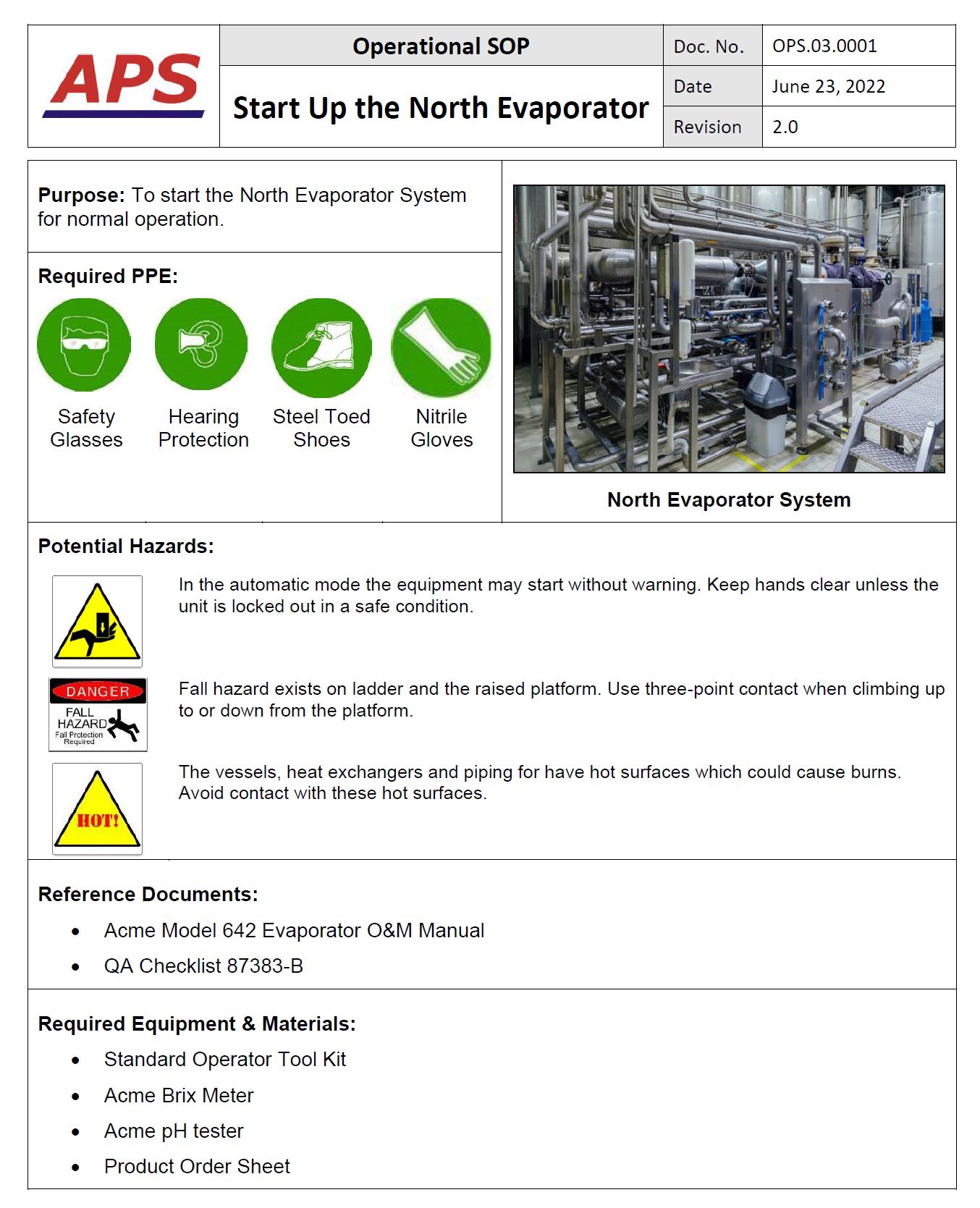

SOP Sample (Equipment Startup)

SOP Writing Services Formats and Templates

For clients without a standard procedure format, APS will design a template that is fine-tuned for your workforce. We include factors such as user reading level, language, work environment, and task criticality in the design of procedures.

Our procedures are structured to meet regulatory standards including ISO, PSM, OSHA, FDA, cGMP, USDA, AIAG, and others.

Did you come here looking for a free Microsoft Word SOP template? No worries. Just give us a call at (610) 987-4050 and we can probably help with that too.

How relevant are SOPs in 2024?

Our clients are telling us that now more than ever, that effective SOPs and work instructions are an essential component of a highly effective organization. Many believe that any business unit without a robust procedure system is doomed to fail.

Also, it’s becoming a challenge to hire people who possess all the skills, knowledge and experience that we’d like. Effective SOPs are needed to serve as training tool and ensure consistent and correct process and task performance.

Let’s face it, as the complexity and sophistication of automated processes continues to increase, we find ourselves asking our employees to take on ever increasing responsibilities. Without a coherent SOP system, we are setting ourselves up to fail.

SOP Writing Services Procedure Types

Since 1994, APS has created many thousands of operations and maintenance procedures including:

Standard Operating Procedures (SOPs) (Startup, Shutdown, Adjustment)

Equipment Changeover and Conversion Procedures

Manufacturing and Assembly Procedures

Standard Work Instructions (SWI, WI, SWP)

Emergency Operating Procedures (EOP)

Corrective Maintenance Procedures

Food and Beverage Production and Packaging Procedures

Equipment and Process System Cleaning and Sanitizing Procedures

Lubrication Procedures

Alarm Response Procedures

Consumer Product Assembly Procedures

Product and Process Quality Inspection Procedures

Equipment Overhaul Procedures

Laboratory Analytical Equipment Procedures

Software Application User Procedures

Administrative Procedures

Personnel Policies & Procedures

APS offers a wide variety of SOP formats and styles. We understand every business has unique requirements and that no single format applies to all industries. We will work closely with your organization to determine the format that will best meet your needs.

For a free quote or for more information on our SOP and Work Instruction writing services, email us at [email protected] or call us at 610-987-4050.