Preventive Maintenance (PM) Procedure Writing Services

APS specializes in creating highly effective, visually-oriented equipment-specific PM procedures.

APS preventive maintenance (PM) procedure writing services are available for all types of industrial process and manufacturing equipment. Our procedures improve the reliability and life expectancy of equipment and improve process efficiency.

Designed for accuracy and ease of use, our maintenance procedures are clearly written and visually-oriented. Our format ensures accuracy and consistency of PM task performance. The level of detail is targeted specifically for your workforce to ensure maximum effectiveness.

Our customers tell us that our preventive maintenance procedures are the best in the industry. These are the procedures that people really use, not just another useless binder that sits on a shelf. Our goal is to provide the the most effective procedures for your organization and your maintenance staff.

Preventive Maintenance Procedure Formats and Templates

Most of our PM procedures are written in Microsoft Word or Excel. They are developed in an easily-edited format, and become the property of the client.

For those clients who are interested, we also offer a state of the art cloud-based electronic procedure system that provides convenient and complete procedure access with robust document control.

APS can also assist your orgnaization with the development of an overall Preventive Maintenance Program and Lockout/Tagout programs.

Sample Preventive Maintenance (PM) Procedure

Click to view a sample Preventive Maintenance (PM) Procedure

Did you come here just looking for a free Preventive Maintenance SOP template for Microsoft Word? No worries. Call us at (610) 987-4050 and we can probably help with that too.

APS develops cost-effective preventive maintenance programs and procedures that:

Prolong equipment life

Increase system and equipment reliability and availability

Reduce spare parts inventory requirements

Improve personnel and environmental safety

Our PM clients include Anheuser-Busch InBev, Novartis, ExxonMobil, Gerber Foods, Carpenter Technology, Verenium Biofuels, ConAgra Foods, Unilever, Fougera Pharmaceuticals, Nestle and many others. Most of our technical personnel have over 20 years of direct, hands-on experience with the operations, maintenance and management of process and manufacturing systems and equipment. APS brings this level of experience and expertise along with creativity, imagination and responsiveness to every project.

APS’ Approach to Preventive Maintenance

APS researches OEM technical literature and other documentation such as industry standards and Government regulations to identify required or appropriate PM tasks and task frequencies. Based on our research and good engineering judgment, Our preventive maintenance (PM) procedure writing services include:

Specific, clearly stated action steps for the performance of each PM task

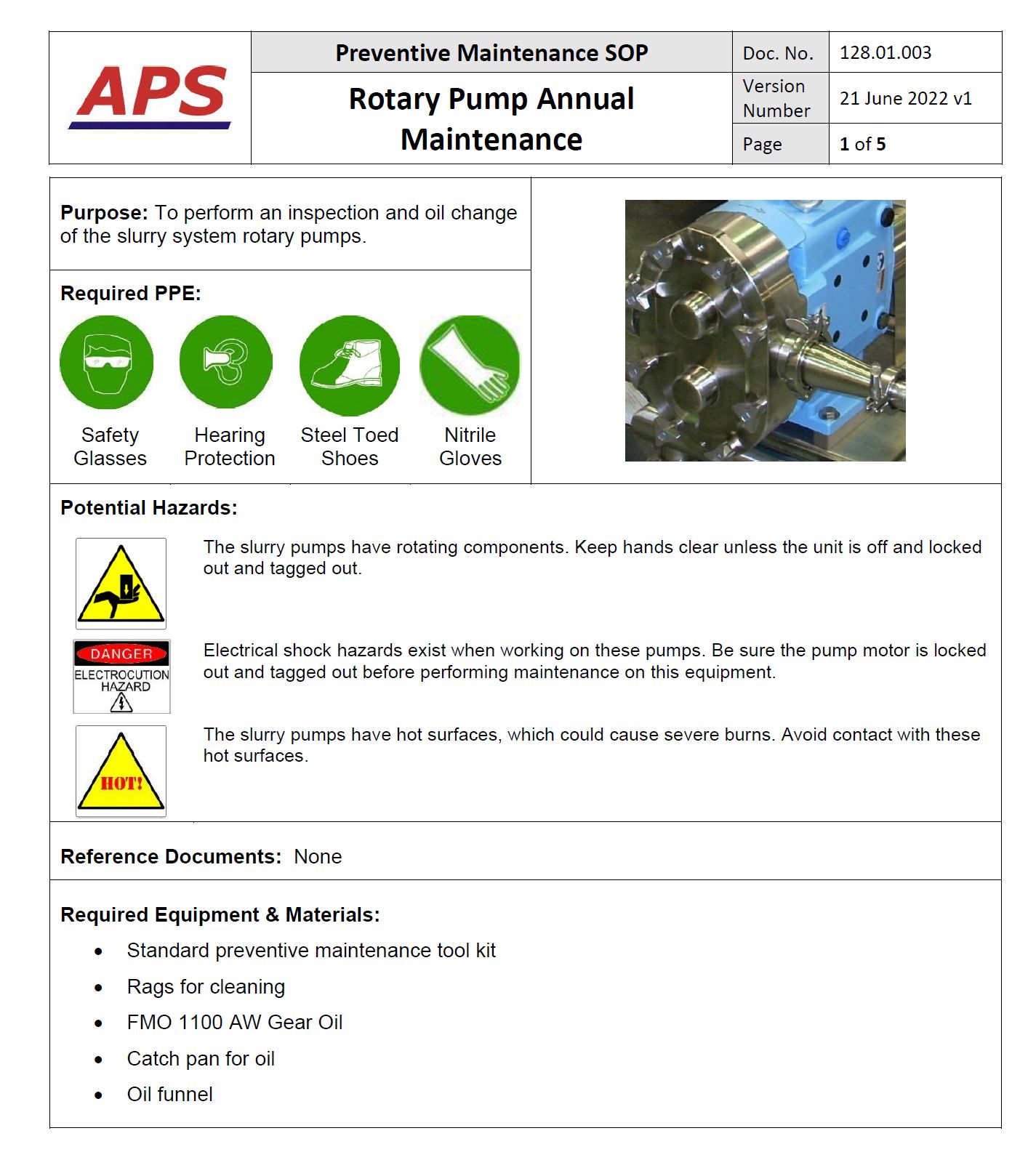

Photographs and/or graphics showing key inspection or lubrication points

Information or data to be recorded during the performance of the PM

Appropriate warnings or cautions relating to specific equipment

Acceptance criteria and action to be taken upon out of specification results

Special tools and equipment needed for PM performance

Recommended frequency of the PM

References to applicable PM source materials

APS Preventive Maintenance (PM) Procedure Writing Services include PM procedures for the following equipment:

Air Handling Units

Chiller Units

Condensers

Natural & Forced Draft Cooling Towers

Fire Pumps and Protection Systems

Filling and Packaging Equipment

Raw Materials Unloading and Transfer

Hot Water Generators

Heating Units & Heat Exchangers

Process Pumps & Compressors

Lighting Systems & Control

Auxiliary Power Generators

Mills

Conveying Systems

Bulk Dry Material Handling Systems

UPS Backup Batteries & Chargers

Food & Pharmaceutical Mixers

Palletizers & Stretch Wrappers

Conveyor Systems

Parking Garage Ventilation Systems

Communication & Security Systems

Hydronic Heating Systems

Fans & Blowers

HVAC Compressors

Cooling Packaged Units

Ammonia Cooling Systems

Process Mixing and Ingredient Handling

Robotic Material Handling Systems

Steam Boilers

Pasteurizing & Sterilizing Systems

Air Compressors & Air Dryers

Plumbing Equipment

Electrical Control Systems

Solar Heating Systems

Mixers & Agitators

Sanitation Systems & Equipment

Packers & Bundlers

Electrical Distribution Equipment

Food Production Kettles

Automatic Guided Vehicles

Accumulators

Sanitation Systems & Equipment

Fire Extinguishers & Safety Equipment

Automatic Garage Door/Grille Operators

Please call us at 610-987-4050 or email info@aps-online.net for more information about APS’ Preventive Maintenance Services or to schedule a site visit.