Lockout-Tagout (LOTO) Procedure Writing Services

APS specializes in Lockout-Tagout (LOTO) programs and procedures for all types of equipment and industrial processes.

APS is a leader in Lockout-Tagout (LOTO) procedure writing services. Our procedures provide worker safety and compliance with OSHA regulations (29 CFR 1910.147).

Our visual LOTO procedures are specially designed with human factors in mind. This format ensures accuracy, completeness, and ease of use. These are the procedures that your people will want to use.

Our Lockout-Tagout services can be scaled to provide as much or as little as required to meet your specific needs. No LOTO job is too large or too small for us.

APS can assist your organization in all phases of your LOTO program. For some of our clients, we provide complete support, including analysis and design of the program, writing all LOTO procedures, and conducting training for affected employees. For other clients, we may perform only a specific portion of these services or work as members of the client’s LOTO team.

LOTO Formats and Templates

Unlike other companies, APS does not use a single “cookie cutter” LOTO procedure format or template. We believe that very company has unique requirements. Your Lockout-Tagout program should perfectly match your needs. We offer a variety of procedure formats, and we can use your existing templates if you desire. Most of our LOTO procedures are created in Microsoft Word, in an easily edited format that becomes the property of our client.

For those clients who are interested in an electronic format, we also offer a state of the art cloud-based electronic procedure system. This system provides continuous online and offline procedure access and positive document and workflow control.

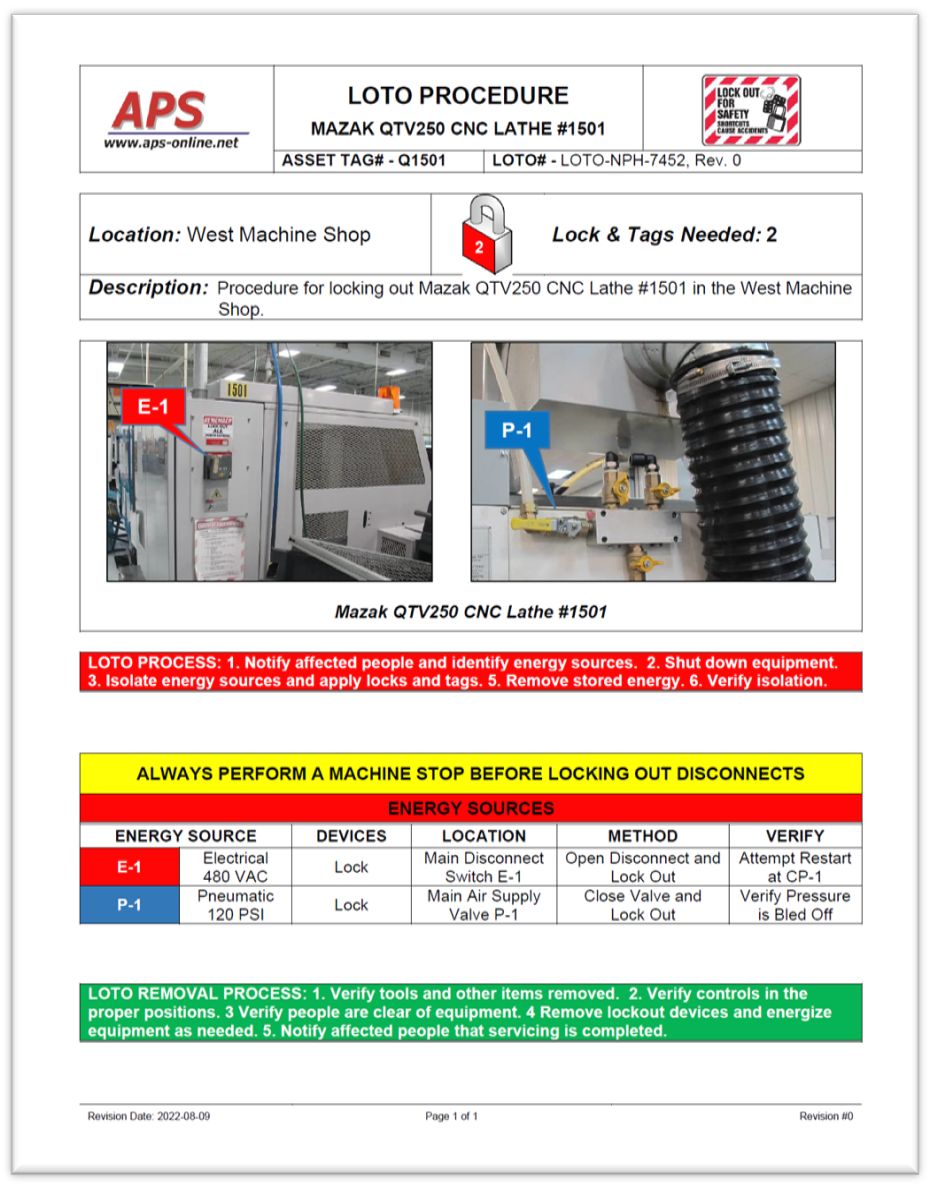

Sample Lockout-Tagout (LOTO) Procedure – Single Page Format

Click Here to view a Sample Lockout/Tagout (LOTO) Procedure (Standard)

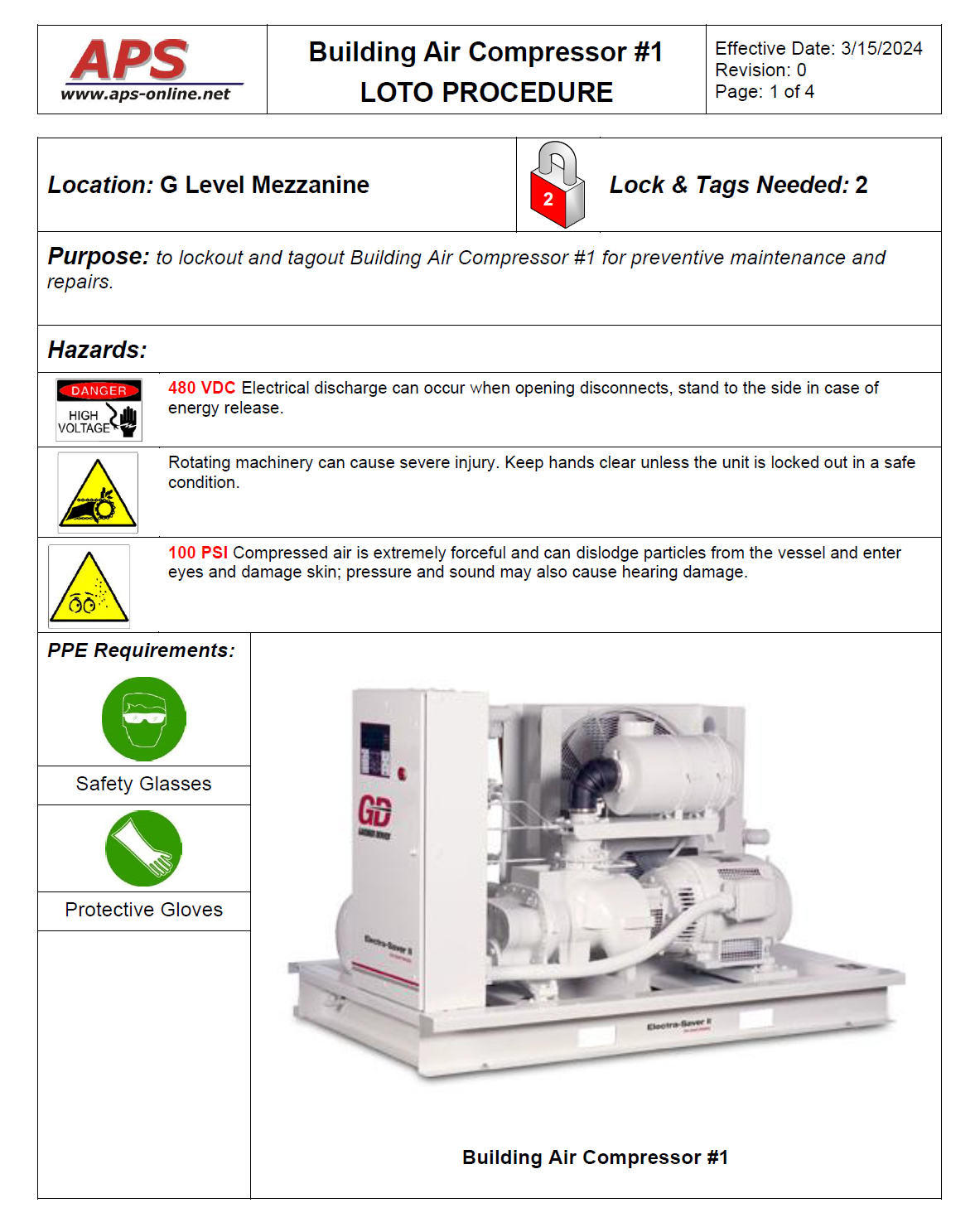

Sample Lockout-Tagout (LOTO) Procedure – Multipage Format

Click Here to view a Sample Lockout/Tagout (LOTO) Procedure (Advanced)

Our Lockout-Tagout (LOTO) procedure writing services include:

Writing lockout/tagout procedures for your equipment

Reviewing and auditing your existing procedures for compliance

Rewriting your existing procedures to incorporate modifications to equipment and transitioning to an efficient format that is easier to use and is compliant with current regulations

Training your employees on proper use of your procedures and OSHA compliance

Teaching your people how to write and maintain effective LOTO procedures

What is Lockout/Tagout (LOTO)?

Lockout-Tagout (LOTO) refers to specific practices and procedures to safeguard employees from the unexpected energizing or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities.

Simply stated, LOTO procedures prevent accidents when your employees are operating and maintaining machines and plant equipment. OSHA regulations (29 CFR 1910.147) (Federal Law) require the control of energy-isolating devices by attaching locks to prevent machines from being operated, or in some cases, tags that provide warning not to operate equipment. LOTO procedures identify energy sources, specify the method of isolating the source and releasing any stored energy, and direct testing to verify energy source removal.

Companies that fall under OSHA regulations must have procedures in place for LOTO of all applicable equipment and machinery. In addition to having the procedures in place, employers are required to conduct annual audits of their procedures to ensure they are in full compliance.

Noncompliance or injuries sustained as a result of inadequate LOTO policies or procedures can result in severe OSHA penalties and expensive fines. More importantly, someone could be injured or killed.

APS specialists will write LOTO procedures for your organization that are accurate, efficient, compliant, and easy to use.

Learn More About our Lockout-Tagout (LOTO) Procedure Writing Services

Click here to review a successful LOTO project summary.

For more information on our LOTO services or a free budgetary cost estimate, please email us at info@aps-online.net or call us at 610-987-4050.