Lockout-Tagout (LOTO) Procedure Writing Services

Applied Performance Strategies, Inc. (APS) develops Lockout-Tagout (LOTO) procedures and programs for industrial equipment across all industries.

Our Lockout/Tagout (LOTO) procedures are custom designed and developed to protect your employees and keep you in full compliance with OSHA 29 CFR 1910.147. We understand that effective energy control procedures must do more than meet regulatory requirements; they must be clear, accurate, and intuitive for every user in your company.

Designed to Fit Your Processes

Our experienced APS LOTO specialists work directly with your team. We will evaluate each piece of equipment, identify energy sources, and create site-specific procedures, customized to your equipment and processes. We serve clients across manufacturing, energy, food and beverage, pharmaceutical, and many other industries.

Highly Visual for Maximum Clarity

Our LOTO procedures are highly visual, combining clear step-by-step instructions with detailed photos, diagrams, and color-coded indicators. This approach makes our procedures intuitive and easy to follow. Our format reduces human error and ambiguity. These are the procedures that people in the real world actually enjoy using.

LOTO Formats and Templates

At APS, we understand that every company has unique requirements. Your Lockout-Tagout program should perfectly match your needs. We offer a variety of procedure formats and templates. We can use your existing templates if you desire. Most of our LOTO procedures are created in Microsoft Word, in an easy-to-edit format that becomes the property of our customers.

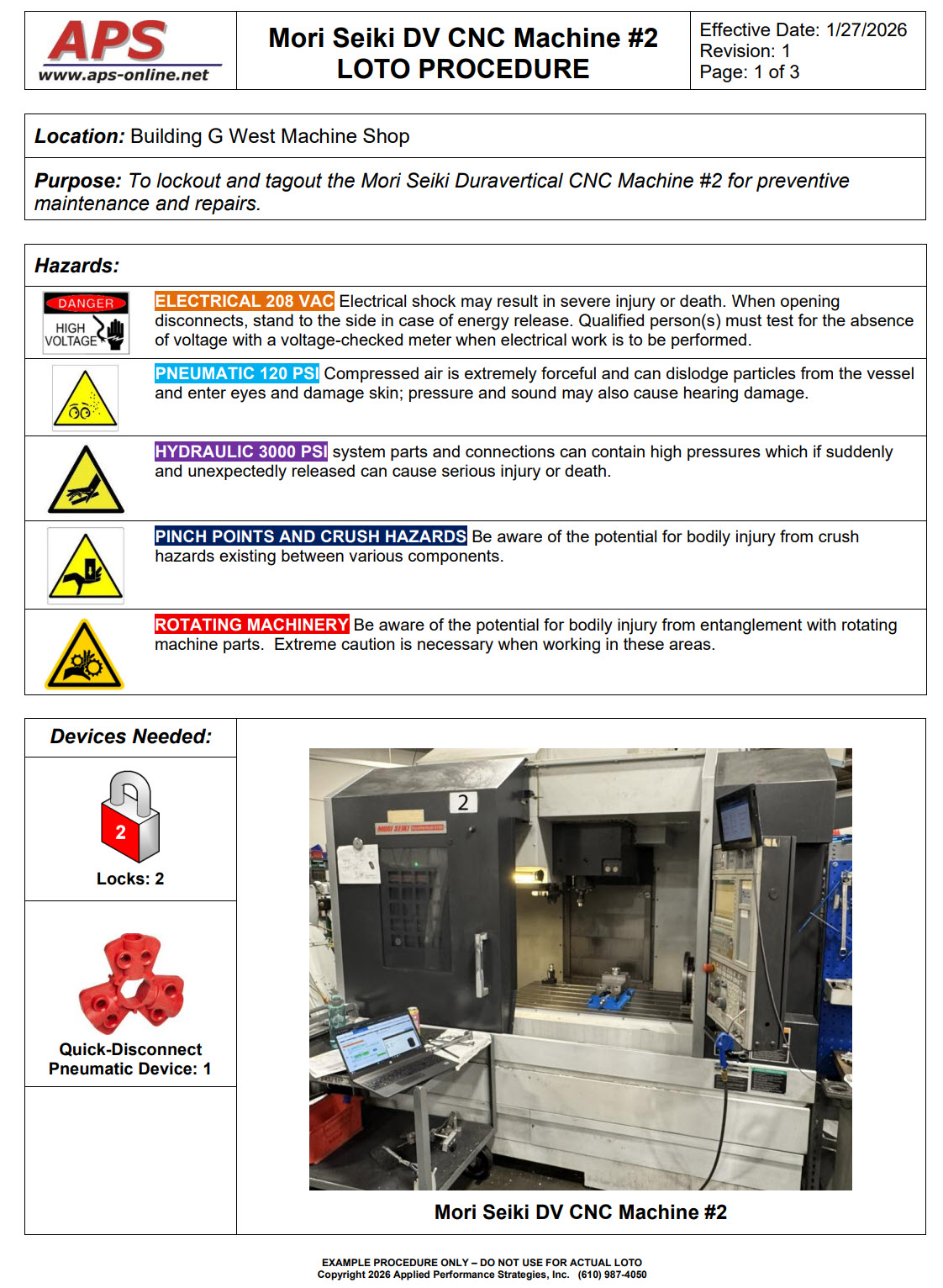

Our Most Popular Sample Lockout-Tagout (LOTO) Procedure – Multipage Format

Click Here to view a Sample Lockout/Tagout (LOTO) Procedure (Advanced)

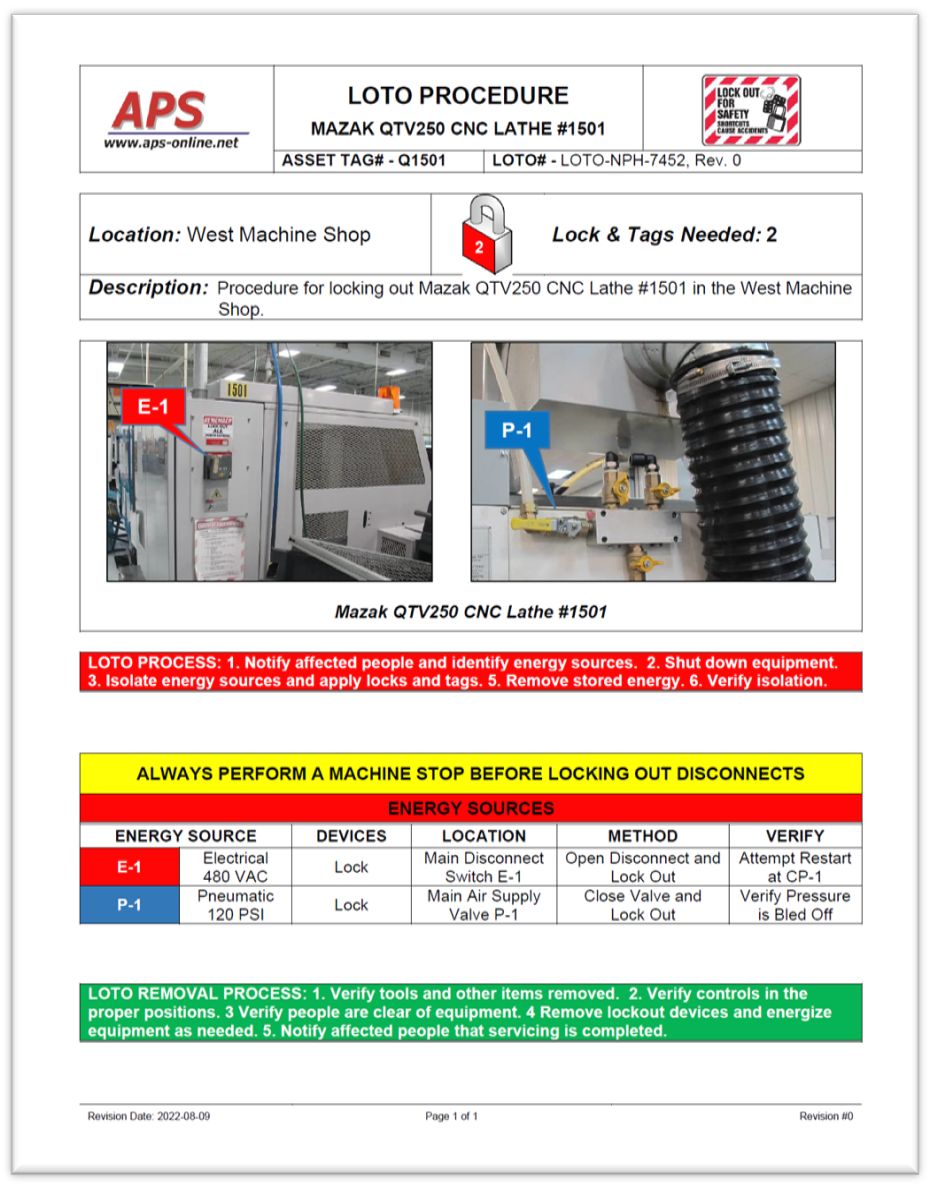

Sample Lockout-Tagout (LOTO) Procedure – Single Page Format

Click Here to view a Sample Lockout/Tagout (LOTO) Procedure (Standard)

Protect People and Simplify Compliance

Whether you’re updating existing energy control procedures or building a new program from the ground up, APS provides a complete solution.

Our Lockout-Tagout (LOTO) procedure writing services include:

Writing lockout/tagout procedures for your equipment

Reviewing and auditing your existing procedures for compliance

Rewriting your existing procedures to incorporate modifications to equipment and transitioning to an efficient format that is easier to use and is compliant with current regulations

Training your employees on proper use of your procedures and OSHA compliance

Teaching your people how to write and maintain effective LOTO procedures

What is Lockout/Tagout (LOTO)?

Lockout-Tagout (LOTO) consists of specific practices and procedures to safeguard employees from the unexpected energizing or startup of machinery and equipment, or the release of hazardous energy during service or maintenance activities.

Simply stated, LOTO procedures prevent accidents when your employees are operating and maintaining machines and plant equipment. OSHA regulations (29 CFR 1910.147) require the control of energy-isolating devices by attaching locks to prevent machines from being operated, or in some cases, tags that provide warning not to operate equipment. LOTO procedures identify energy sources, specify the method of isolating the source and releasing any stored energy, and direct testing to verify energy source removal.

Companies that fall under OSHA regulations must have procedures in place for LOTO of all applicable equipment and machinery. In addition to having the procedures in place, employers are required to conduct annual audits of their procedures to ensure they are in full compliance.

Noncompliance or injuries sustained as a result of inadequate LOTO policies or procedures can result in severe OSHA penalties and expensive fines. More importantly, someone could be injured or killed.

APS specialists will write LOTO procedures for your organization that are accurate, efficient, compliant, and easy to use.

Learn More About our Lockout-Tagout (LOTO) Procedure Writing Services

Click here to review a successful LOTO project summary.

For more information on our LOTO services or a free budgetary cost estimate, please email us at [email protected] or call us at 610-987-4050.